Range of application for cold drawn section steel:

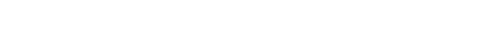

1. Special Cold drawn section steel for diesel oil pump;

2. Cold-drawn section steel for mechanical matching tooth germ;

3. Special cold drawn section steel for textile guide rail;

4. Cold drawn section steel for industry supporting knitting machine chain block and knitting machine slider;

5. Cold drawn channel steel with grooved section for automatic equipment / electrical industry;

6. Hydro generator positioning ribbed section steel;

7. Cold drawn section steel for forklift accessories, forklift side positioner and forklift beam

Advantages of our cold drawing production:

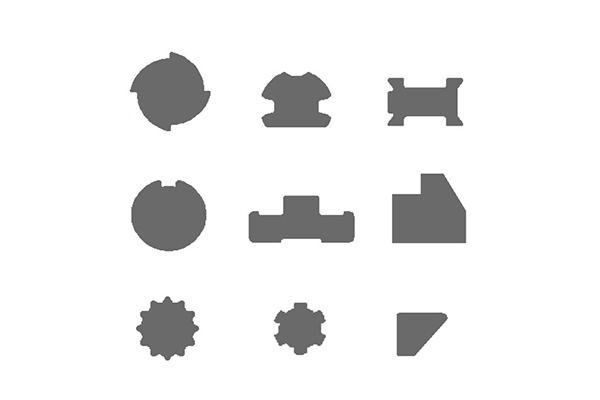

1. Hot rolled and cold drawn section steels with complex cross-section shapes can be customized;

2. Special materials, special-shaped steel and small steel can be customized;

3. Low starting point of customization and small quantity of special-shaped steel with complex section;

4. Less investment in the early stage, high product surface roughness, high finish and high dimensional accuracy;

5. We have 500 rolling mill, 350 rolling mill, 250 rolling mill and 200 rolling mill. 8 tons, 20 tons, 60 tons, 100 tons and other high-precision drawing lines, large-scale computer numerical control roll processing unit, numerical control milling machine, planer, 1m numerical control vertical lathe, shot blasting machine, raw material crystal structure heat treatment furnace, high-speed circular saw, band saw, straightener, drilling and milling and other equipment form a one-stop production line for hot rolling, cold drawing and deep processing.